151 MODERN METHOD OF CONSTRUCTION (PART 1) - ppt video online download

4.8 (746) · $ 11.00 · In stock

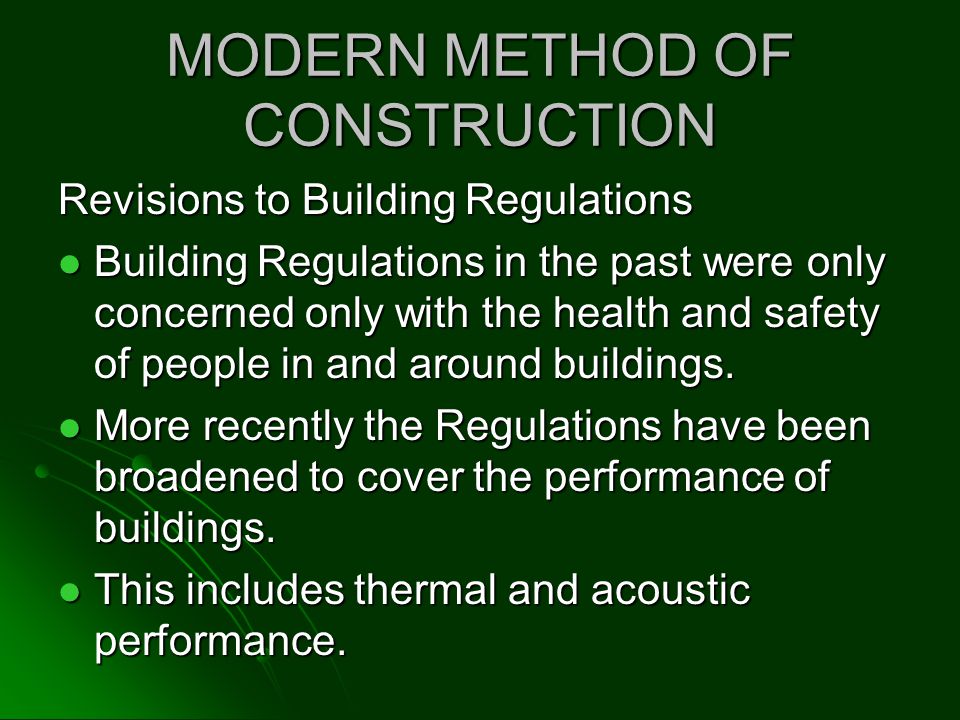

MODERN METHOD OF CONSTRUCTION Revisions to Building Regulations Building Regulations in the past were only concerned only with the health and safety of people in and around buildings. More recently the Regulations have been broadened to cover the performance of buildings. This includes thermal and acoustic performance.

151 MODERN METHOD OF CONSTRUCTION (PART 1)

Dr f Dejahang (BSc CEng, BSc (Hons) Construction Mgmt, MSc, MCIOB, PhD)

Revisions to Building Regulations. Building Regulations in the past were only concerned only with the health and safety of people in and around buildings. More recently the Regulations have been broadened to cover the performance of buildings. This includes thermal and acoustic performance.

House builders are concerned with meeting higher standards, but with the prospect that performance might be tested after construction. This can lead to costly remedial work if performance falls short of the standard required.

Some house builders are looking at MMC as a potential way of providing more predictable performance in the completed dwelling.

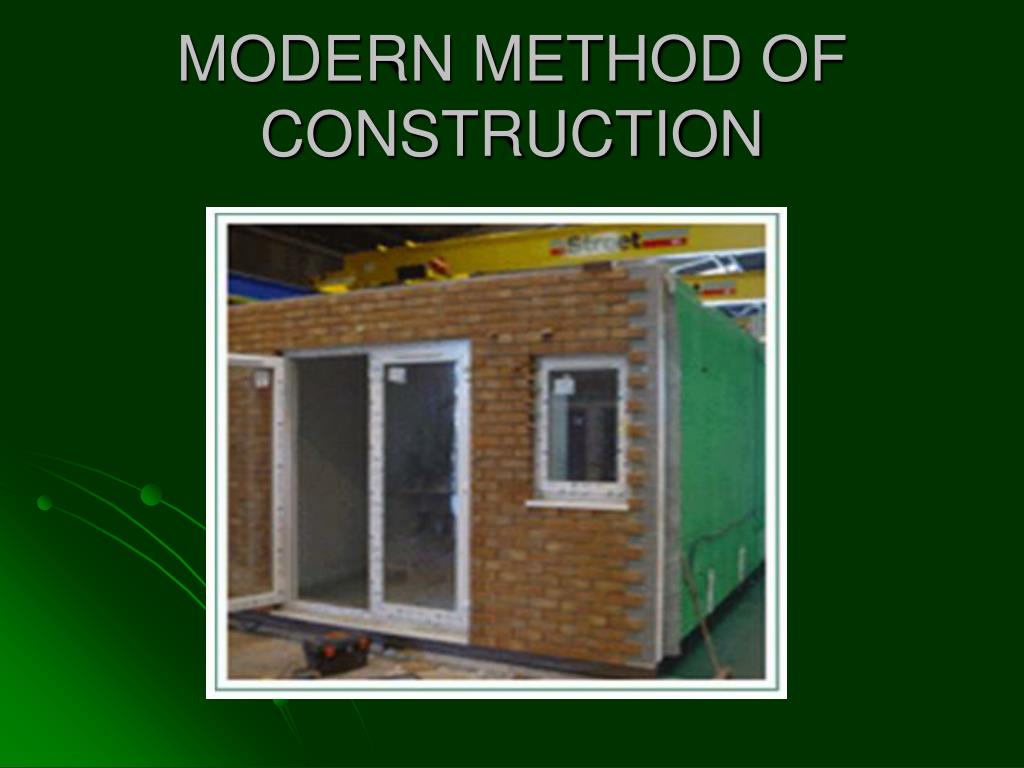

Modern methods of construction is a collective term used to describe a number of construction methods. The methods being introduced into UK house building differ significantly from so-called conventional construction methods such as brick and block.

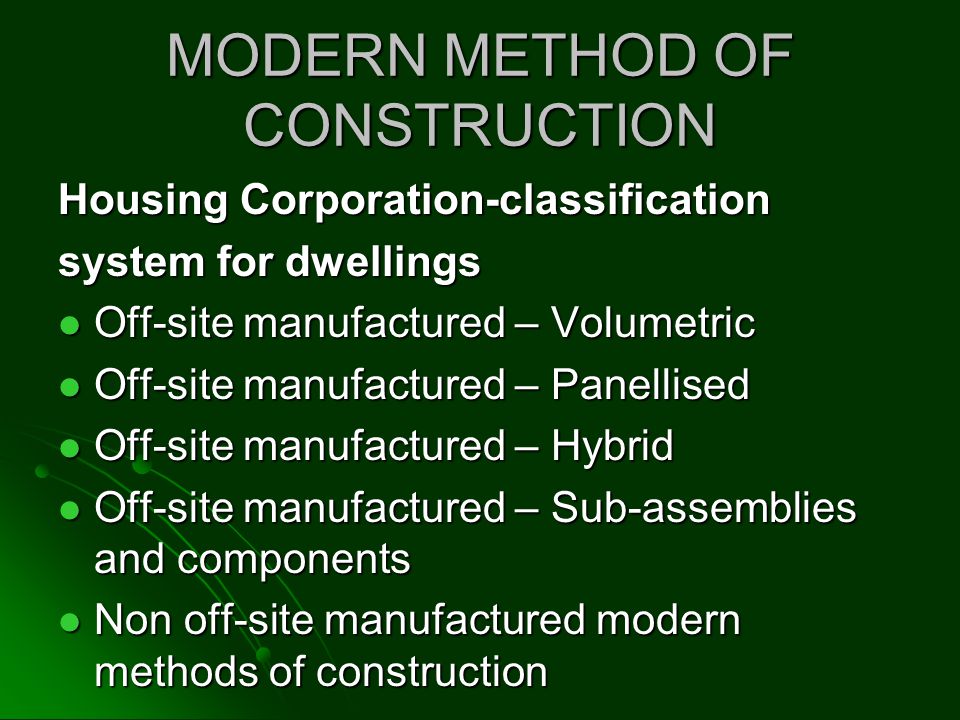

Housing Corporation-classification. system for dwellings. Off-site manufactured – Volumetric. Off-site manufactured – Panellised. Off-site manufactured – Hybrid. Off-site manufactured – Sub-assemblies and components. Non off-site manufactured modern methods of construction.

Definition based on attributes such as efficiency and quality. Most MMC being constructed at present is subject to Housing Corporation grants. The information in this PPT is therefore based on that system.

Three-dimensional units produced in a factory, fully fitted out before being transported to site and stacked onto prepared foundations to form the dwellings.

VOLUMETRIC / MODULAR CONSTRUCTION Volumetric construction (often referred to as modular construction) involves the production of three-dimensional units in controlled factory conditions, prior to transportation to site.

Modules can be delivered to site in a variety of forms. some may simply be a basic empty shell awaiting on-site finishing. others may have already been completely fitted out with all the necessary internal/external finishes and services, and be purely ready for on-site assembly.

The maximum size of a volumetric unit is only really determined by the practicalities of transportation, road and site access. The strength and rigidity of the modules is a very important factor and must be sufficient enough to allow them to be securely transported and craned into place on-site without being damaged.

The majority of the volumetric construction in the UK to date has been used in: Hotels. student accommodation. health authorities. NHS Trusts and fast food sectors.

Family-sized accommodation is becoming increasingly popular. Terraced ‘town-house’ might typically be broken down in four basic modules, plus a roof and even possibly a dormer window module.

Weatherby Building System (WBS’s) range of systems are ideal for use with volumetric modules and include traditional polymer cement renders, thin-coat silicone & acrylic finishes and brick slip cladding, which can all be applied either prior to site delivery or after the modules have been finally positioned on-site.

Some of the benefits of Volumetric. Construction. More cost effective that traditional methods of construction. Rapid on-site assembly time. Improved quality. Reduced defects & snagging.

Less disruption on-site. Better predictability and control. Good thermal, acoustic and wind resistant properties. Fantastic choice of external finishes available.

Arquitectonica Trinity Place San Francisco, California.

The buildings are conceived as a series of rectangular prisms that rest on each other. Each building has a different volumetric composition that results in an individual expression within the common vocabulary of the block.

The arrangement of volumes is intended to form a multidimensional neighborhood of buildings, with some structures expectedly anchored firmly on the ground, some less expectedly suspended above other volumes, some informally overlapping. A large vertical gateway, with a grand staircase, leads up to the interior park-like courty.

Panellised construction systems. Flat panel units built in a factory and transported to site for assembly into a three-dimensional structure or to fit within an existing structure.

Systems can include wall, floor and roof panels to create the complete structural shell. Factory-made structural floor and roof panels are known as ‘cassettes’.

There are many different types of panel, the. Main-types are: Open panels: panels delivered to site where insulation, windows, services and linings are fitted. All structural components are visible.

Panels can be structural (transmitting load to the foundations) or non-structural (used as non-load bearing separating walls and partitions).

Closed panels: panels based on a structural framing system (such as the type used for open panel systems), which can have factory fitted windows, doors, services, internal wall finishes and external. cladding. The internal structural components can only be seen around the perimeter of the panel.

Concrete panels: structural wall panels, which can include cladding (often bricks or brick slips), insulation materials, windows and doors. Composite panels: panels made from a combination of different materials that act together to provide structural support.

Structural insulated panels are a specific form of composite panel. Structural insulated panels (SIPS): sandwich construction comprising two layers of sheet material bonded to a foam insulation core. They do not rely on internal studs for their structural performance.

Used primarily as wall and roof panels. Infill panels: non-loadbearing panels inserted within a structural frame. Any type of panel can be used although framed panels are more common. Masonry can also be used. it.

Curtain walling: vertical building enclosure system that supports no loads other than its own weight and the environmental loads that act upon.

Volumetric units integrated with panellised. systems. Hybrid construction is also referred to as semivolumetric construction. Highly serviced areas such as kitchens or bathrooms can be constructed as volumetric units, with the rest of the dwelling constructed with panels.

What is SIP s, Structural Insulated Panels

Steel SIP s are engineered panels made from a dense core of EPS (expanded polystyrene) sandwiched between two exterior layers of galvanized steel, resulting in a solid one-piece that provides structural framing, insulation, and exterior sheathing. The 200mm wide interlocking panels are strong.

First few courses; note the sandy soil

Closer View of first few courses

Different wall thicknesses shown

Understanding the role of digital technologies in education: A

upload.wikimedia.org/wikipedia/en/5/51/Minecraft_c

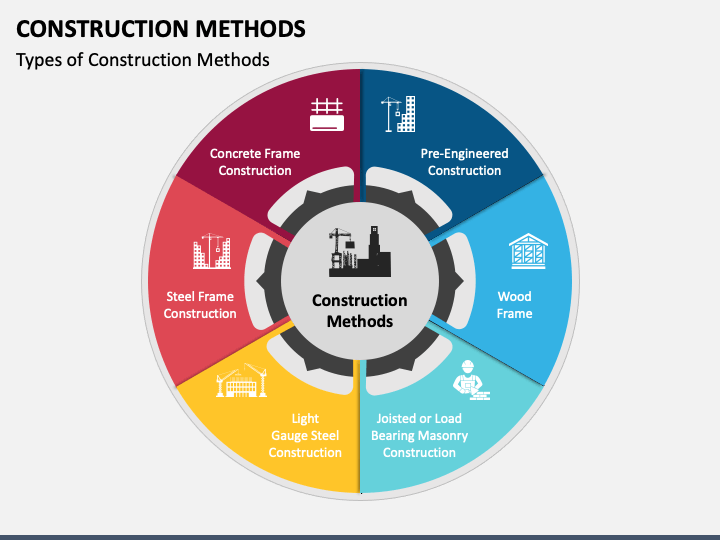

Construction Methods PowerPoint Template and Google Slides Theme

PPT 151 MODERN METHOD OF CONSTRUCTION (PART 1) PowerPoint, 44% OFF

075 Modern Methods of Construction

MODERN CONSTRUCTION METHODS

Harrison K. Banda posted on LinkedIn

Make a Sentence Activity (Teacher-Made) - Twinkl

What Is a Mobile App - All You Should Know as a Future Product

Free Google Slides Projects :: Photos, videos, logos

151 MODERN METHOD OF CONSTRUCTION (PART 1) - ppt video online download

PPT - 151 MODERN METHOD OF CONSTRUCTION (PART 1) PowerPoint

Harlan Krumholz > Specialists > Yale Medicine